lee hardness testing kit instructions|lead hardness tester for sale : trade $3.00. Add to cart. Add to wishlist. Add to compare list. Email a friend. Instructions for the Lead . Prepreg carbon fibers are those that have already been pre-impregnated with resin before they ship to clients. This simplifies the molding process and yields a material that, once cured, is .Autoclaves heat their contents to 121°C, which is 21°C over the boiling point of water. To prevent the solutions from boiling over/vaporizing, the autoclave chamber is pressurized during this process. Most buffers and other solutions used in any lab are sterilized before use to prevent bacterial and fungal growth . See more

{plog:ftitle_list}

These investigations encouraged Skoog, Miller, and co-workers in 1955 to isolate and identify Kinetin, a highly active cell-division stimulator, from autoclaved herring sperm DNA.

lee lead hardness tester manual

.00. Add to cart. Add to wishlist. Add to compare list. Email a friend. Instructions for the Lead .Instructions. Visit our knowledgebase for additional information. To view/download, click on the ..00. Add to cart. Add to wishlist. Add to compare list. Email a friend. Instructions for the Lead Hardness Test Kit code = 90924.Instructions. Visit our knowledgebase for additional information. To view/download, click on the instruction sheet part number or description. Instructions are best viewed and printed with Adobe Acrobat. Reloading Dies. Reloading Presses & Kits. Inline Bullet Feeder. Automatic Processing Press (App) & Accessories Instructions. Powder Handling.

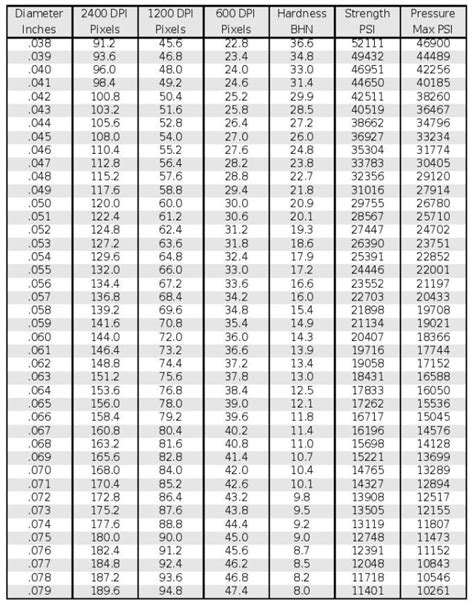

The hardness tester consists of three items (see fig. 1). They are: Indenter – At first glance looks like a regular seating or reloading die. The body of the indenter is threaded 7/8 X 14 in order for it to screw directly into all standard reloading presses.A 5-minute video covering the basics of cast bullet hardness and demonstrating Lee Precision's Lead Hardness Tester. The Lee kit consists of a calibrated ball indenter to make dents in the test specimen under a set load, a V block gadget to hold bullets in a horizontal position for testing, and a small 20X optical microscope to measure the diameter of the dent.

The Lead Hardness tester does not require any routine maintenance other than a light film of gun oil to prevent rust. Do not disassemble the tester as you may loose any installed calibration shims. Do not subject the indenter ball to impact or hardened surfaces.We show you how to use the Lee Lead Hardness Tester Kit. This is important for matching your alloy strength to your load's pressure. Also available at www.. Test Hardness of Pure Lead. The hardness tester will only be accurate over the hardness range listed in the instructions. The indenter ball diameter determines the range over which the tester is accurate. The tester comes in one of Lee’s standard plastic cases complete with a ball-indenter, v-block, compact 20x microscope, and a simple set of instructions. Installation is a snap; the operator begins by sliding the included v-block into the ram of a single stage press, then threads the indenter into the top like any other reloading die.

Lee Lead Hardness Test Kit will determine the exact Brinnell Number of an alloy in a simple 6 step process. Included is the Lee Pocket Micro Scope Product information.00. Add to cart. Add to wishlist. Add to compare list. Email a friend. Instructions for the Lead Hardness Test Kit code = 90924.Instructions. Visit our knowledgebase for additional information. To view/download, click on the instruction sheet part number or description. Instructions are best viewed and printed with Adobe Acrobat. Reloading Dies. Reloading Presses & Kits. Inline Bullet Feeder. Automatic Processing Press (App) & Accessories Instructions. Powder Handling.

The hardness tester consists of three items (see fig. 1). They are: Indenter – At first glance looks like a regular seating or reloading die. The body of the indenter is threaded 7/8 X 14 in order for it to screw directly into all standard reloading presses.A 5-minute video covering the basics of cast bullet hardness and demonstrating Lee Precision's Lead Hardness Tester.

The Lee kit consists of a calibrated ball indenter to make dents in the test specimen under a set load, a V block gadget to hold bullets in a horizontal position for testing, and a small 20X optical microscope to measure the diameter of the dent.

The Lead Hardness tester does not require any routine maintenance other than a light film of gun oil to prevent rust. Do not disassemble the tester as you may loose any installed calibration shims. Do not subject the indenter ball to impact or hardened surfaces.

We show you how to use the Lee Lead Hardness Tester Kit. This is important for matching your alloy strength to your load's pressure. Also available at www..

Test Hardness of Pure Lead. The hardness tester will only be accurate over the hardness range listed in the instructions. The indenter ball diameter determines the range over which the tester is accurate. The tester comes in one of Lee’s standard plastic cases complete with a ball-indenter, v-block, compact 20x microscope, and a simple set of instructions. Installation is a snap; the operator begins by sliding the included v-block into the ram of a single stage press, then threads the indenter into the top like any other reloading die.

lee lead hardness tester instructions

is the written driving test hard in california

Switch, Pressure,N.C. 1/4" BSP,Set 0.2 Bar. Report a Problem?

lee hardness testing kit instructions|lead hardness tester for sale